Arizona State University has partnered with Applied Materials Inc. to establish a cutting-edge research, development and prototyping facility in the Valley.

The partnership includes a $270 million investment, with $200 million from Applied Materials for equipment operation, maintenance, research and scholarship funding; $30 million from the Arizona Commerce Authority; $17 million from ASU and $25 million in Arizona New Economy Initiative funding and bonds.

“Applied Materials is excited to build upon our successful track record of collaboration with Arizona State University by adding the Materials-to-Fab Center to our university innovation network,” says Gary Dickerson, president and CEO of Applied Materials. “Applied envisions the center at ASU playing a key role in accelerating materials engineering innovations, commercializing academic research and strengthening the pipeline of future semiconductor industry talent.”

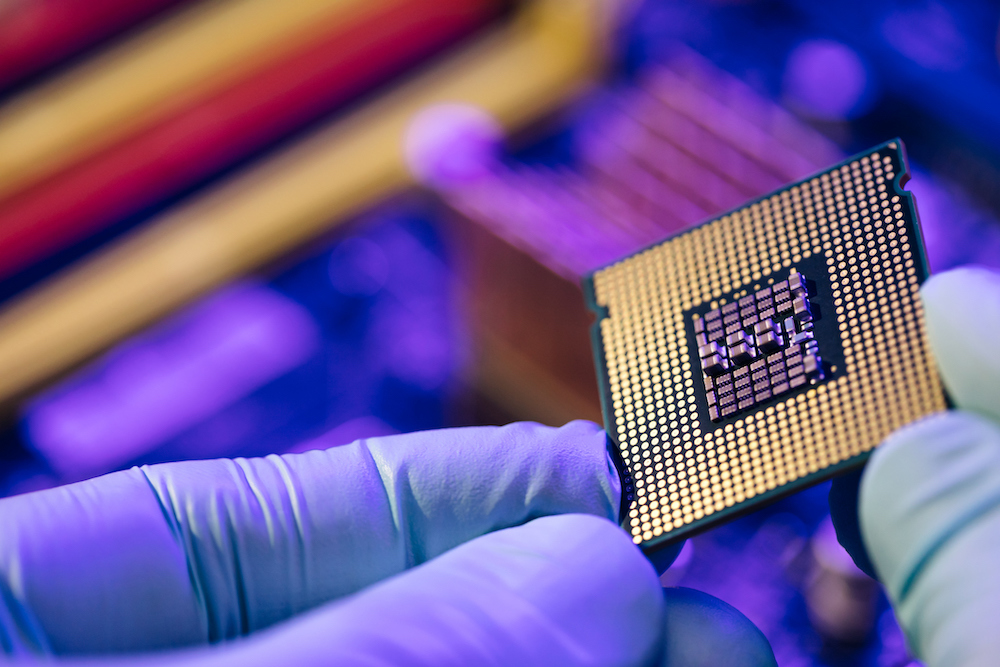

The 10,000-square-foot facility is currently undergoing design and is expected to span three floors, with plans to open within two years. It will serve as a hub for students and faculty, providing learning and research opportunities. In this collaborative environment, students can work alongside industry partners, startups, government entities and academic institutions to transform innovative ideas into fab prototypes.

"When I speak to companies, I say, ‘What is the thing you are most worried about?’ It’s [the] workforce. It's having people who are capable of working with this very state-of-the-art equipment,” Sally Morton, executive vice president of ASU’s Knowledge Enterprise, told the Phoenix Business Journal. “So it's almost like we're allowing our students to walk into a TSMC fab and really be part of it before they leave the university, and we're really excited about having that capability for our students.”

At the Materials-to-Fab Center, students will have the opportunity to work with advanced 300mm equipment used in leading-edge production fabs. The facility will offer end-to-end chip capabilities, including research, development, prototyping and fabrication, to support ideas generated at the university level and meet the growing demand for a skilled workforce in the semiconductor industry.

“Generally, students and faculty would not have access to the state-of-the-art 300 millimeter types of equipment," says Morton. "We very much want our students to be part of this ecosystem and to learn to use these tools so they are even more saleable when they get out on the market."

The MTF Center will not only benefit companies across the Valley, but also foster academic-industry collaboration in line with the objectives of the CHIPS and Science Act.

“Applied Materials and Arizona State University already enjoy a close partnership, and this new alliance around the Materials-to-Fab Center will take things to a new level,” says ASU President Michael Crow. “But what is more important than the partnership is what it will do for the industry and the country. This is the beginning of a reconfiguration of the way to accelerate discovery and translational research outcomes in response to real-world challenges and the development of next-generational processes, materials, equipment and workforce.”

Applied Materials is the world’s largest semiconductor manufacturing equipment provider, supplying semiconductor manufacturing and display equipment globally. In addition to the facility at ASU Research Park, Applied Materials announced plans to construct the Equipment and Process Innovation and Commercialization Center in Silicon Valley, further solidifying their commitment to advancing materials deposition technology.

“The MTF Center will accelerate the development, commercialization and manufacturing of next-generation U.S. semiconductor-based technologies while bolstering the state’s infrastructure, workforce and research capabilities,” says Sandra Watson, president and CEO of the Arizona Commerce Authority. “We’re proud to play a leading role supporting this first-of-its-kind partnership between one of the world’s leading semiconductor companies and America’s most innovative university.”

Arizona's semiconductor market has witnessed significant investment since 2020, making it a growing hub in the industry. With leading semiconductor producers, suppliers, defense contractors and a thriving startup community, educational institutions like ASU have prioritized expanding their chip manufacturing programs to meet the demand for a skilled workforce.

“High-quality universities are one of America’s greatest advantages in the global competition for semiconductor manufacturing, research and development. What Applied Materials and Arizona State University are doing is smart, and the successful implementation of the Materials-to-Fab facility will establish an innovation and job-creation engine for the semiconductor ecosystem in Arizona,” says Arizona Governor Katie Hobbs.

Applied Materials also announced plans to create an endowment fund to provide scholarships to first-generation and/or underrepresented minority students at ASU’s Ira A. Fulton Schools of Engineering. ASU students will also have access to the Applied Materials Momentum Fund, which provides grants to women pursuing engineering degrees, facilitating their entry into the semiconductor industry.

“ASU and Applied Materials have created a foundation of collaboration, and we have already seen its value. What this alliance will do is expand impact, deliver the mechanisms for finding new ways of doing things and, if we are successful, it will yield results that we can use to innovate again,” says President Crow. “This is work that is never finished, so as exciting as it is to be where we are today, you can expect to hear more from us on this front in the future, and we encourage others to take this model and replicate it.”

This collaboration builds upon ASU's ranking as the #1 school in innovation for eight consecutive years, solidifying its position as a leader in technology and creating unparalleled opportunities for students.

To learn more about Arizona State University, visit www.asu.edu.